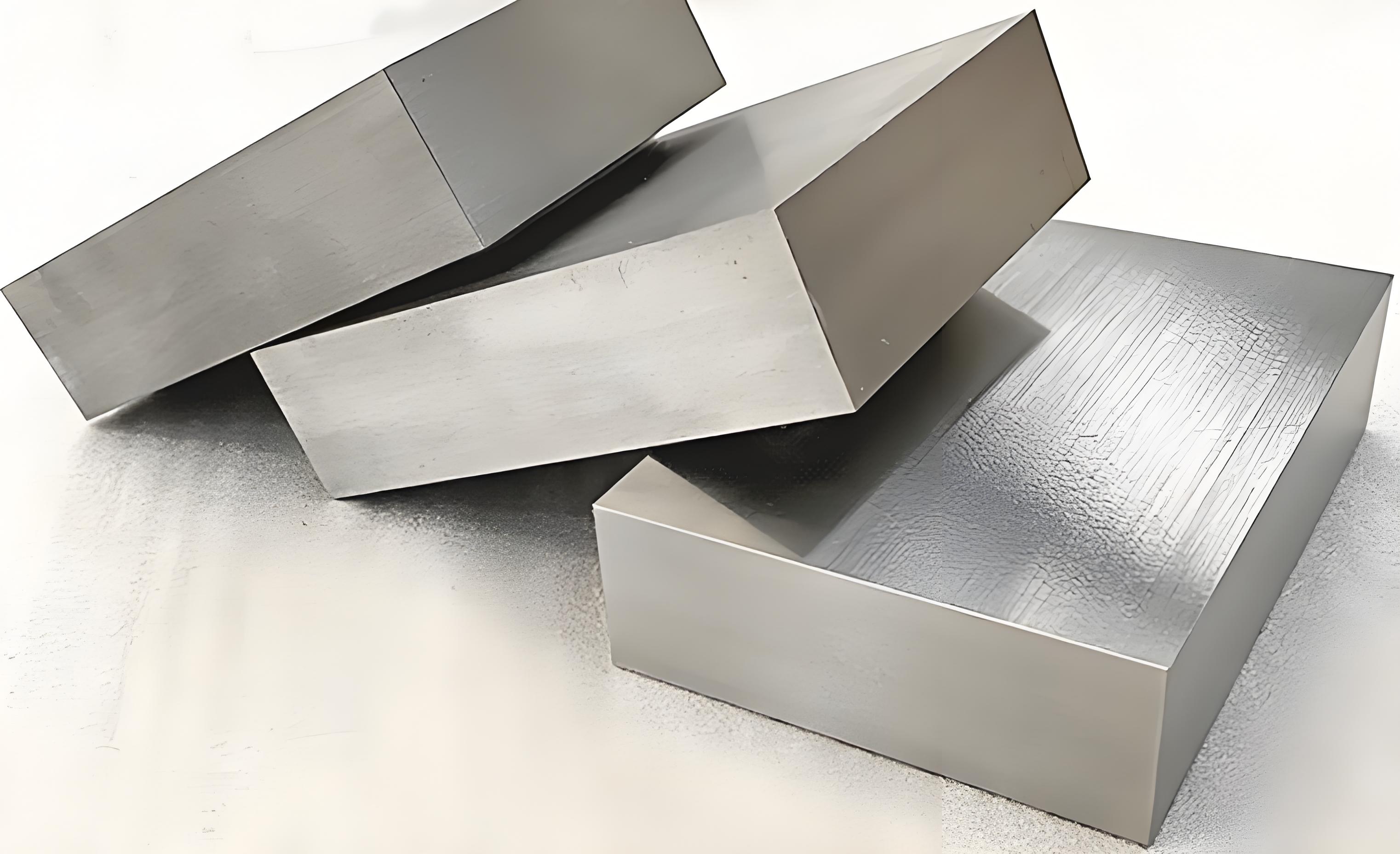

In the world of advanced manufacturing—from aerospace component production to medical device development, chemical equipment fabrication to semiconductor processing—access to high-quality, precisely sized titanium blocks is the foundation of successful projects. Our Various Sizes High Purity Titanium Block Custom Cutting service bridges the gap between raw Titanium Materials and your unique production needs, delivering tailored solutions crafted from premium titanium blocks, titanium alloys, and Titanium Forgings. Whether you require small, precision-cut pieces or large-format blocks, we combine industry-leading purity with flexible cutting to power your most critical applications. Uncompromising Purity: The Core of Our Titanium Blocks

At the heart of our offering is our commitment to high purity—because even the smallest impurity can compromise performance in demanding industries. Our titanium blocks boast:

99.99%+ High Purity: Sourced from top-tier titanium materials, our blocks eliminate contaminants that risk structural weakness, chemical reactivity, or thermal instability. This makes them ideal for applications like medical implant machining (where biocompatibility is non-negotiable) and semiconductor tooling (where material purity protects sensitive electronics).

Industry-Proven Titanium Alloys: Beyond pure titanium, we offer alloyed blocks tailored to specific needs. Choose from Ti-6Al-4V (for exceptional strength-to-weight ratio in aerospace), Ti-5Al-2.5Sn (for cryogenic resistance in industrial cooling systems), or Ti-6Al-4V ELI (for enhanced biocompatibility in medical devices)—all available in customizable sizes.

Titanium Forging-Derived Blocks: For projects requiring superior mechanical properties, we provide blocks processed from titanium forgings. Forged titanium offers increased density, fatigue resistance, and impact strength, making these blocks perfect for high-stress components like turbine parts or heavy machinery components.

Flexible Custom Cutting: Tailored to Your Exact Specifications

No two projects are the same—and neither should your titanium blocks be. Our custom cutting service ensures you get exactly what you need, with:

Diverse Size Range: From small blocks (as compact as 10mm x 10mm x 10mm) for precision machining to large-format blocks (up to 1000mm x 500mm x 300mm) for industrial-scale fabrication, we cover every size requirement. Need something outside this range? Our team can accommodate custom dimensions.

Precision Cutting Technologies: Using advanced CNC cutting, waterjet cutting, and laser cutting systems, we achieve tolerances as tight as ±0.05mm. This level of accuracy minimizes material waste, reduces post-processing time, and ensures your blocks align perfectly with your design blueprints.

Custom Surface Finishes: Choose from raw mill finish (for further machining), polished finish (for applications requiring corrosion resistance and aesthetics), or sandblasted finish (for improved adhesion in coating processes). We tailor every detail to match your production workflow.

Why Choose Our Titanium Block Custom Cutting Service?

In a market saturated with generic titanium products, we stand out by prioritizing your convenience and project success. Here’s what sets us apart:

End-to-End Material Expertise: We don’t just cut blocks—we source, test, and process our titanium materials (including titanium alloys and forgings) in-house, ensuring full control over quality from start to finish.

Rigorous Quality Assurance: Every titanium block undergoes comprehensive testing, including chemical composition analysis (via spectrometry), dimensional inspection (using CMM), and purity verification (to confirm 99.99%+ standards). We only ship products that meet ASTM, AMS, and ISO certifications.

Fast Turnaround: Our streamlined production process—paired with a large inventory of pre-stocked titanium blocks—means we can fulfill standard size orders in as little as 3–5 business days. For custom sizes, we offer expedited options to meet tight deadlines.

Sustainable Practices: We prioritize eco-friendly manufacturing, including recycling titanium scrap from cutting processes and using energy-efficient machinery, to reduce our environmental footprint without compromising quality.

Get Your Custom Titanium Blocks Today

Whether you’re machining medical implants, building aerospace components, or fabricating chemical processing equipment, our Various Sizes High Purity Titanium Block Custom Cutting service is designed to simplify your supply chain and elevate your projects.

Contact us now to share your specifications (size, material type, finish, and quantity), request a free sample, or get a detailed quote. Our team of titanium experts will work with you to create a solution that fits your needs—and your budget.