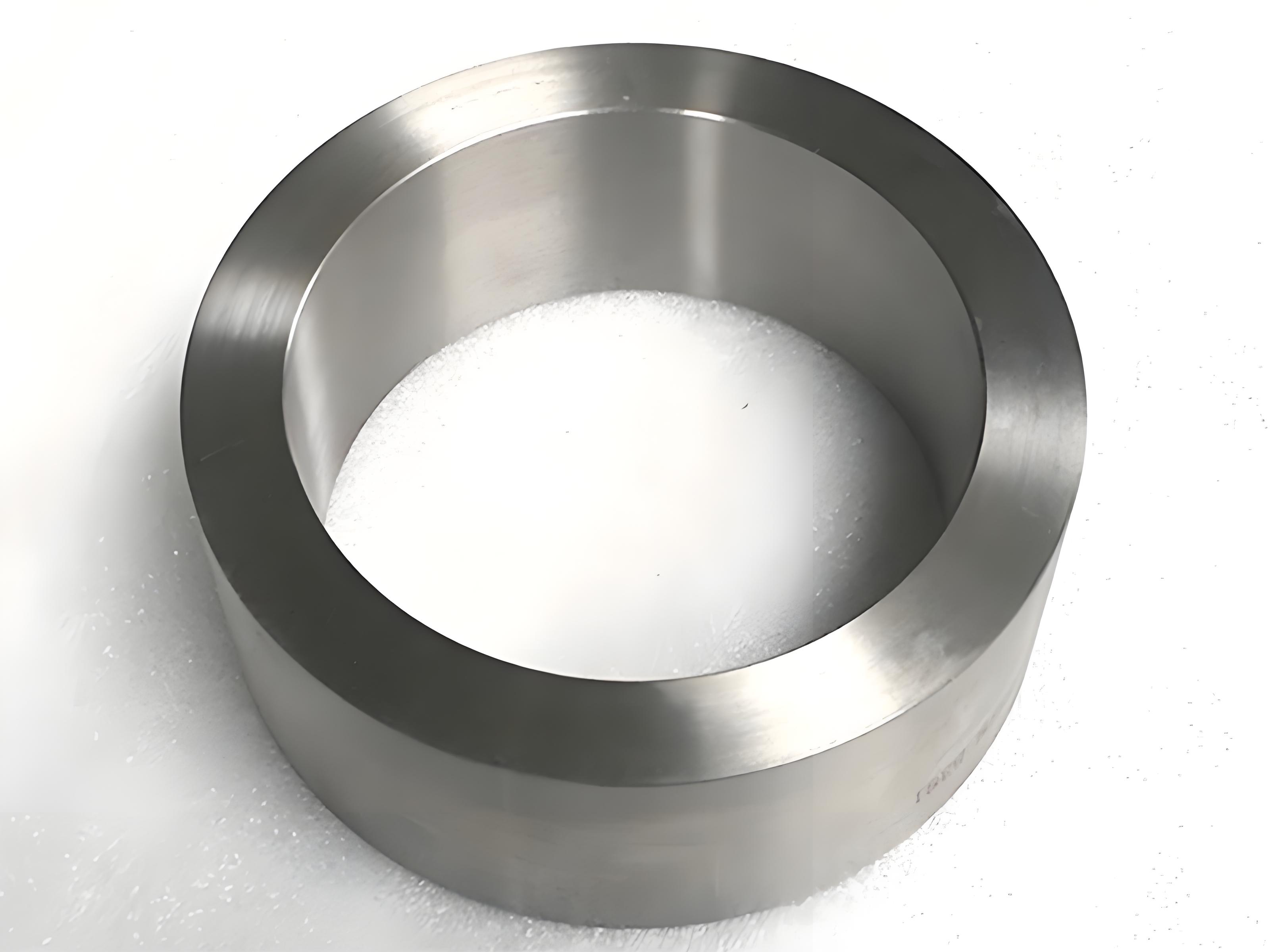

In industries where precision meets durability—from aerospace engine components to medical equipment, and industrial machinery to automotive powertrains—titanium ring machined parts stand as indispensable components. Their ability to withstand extreme conditions while maintaining dimensional accuracy makes them a top choice for critical applications. Our Titanium Ring Machined Parts, crafted through high-precision CNC machining and sourced from premium Titanium Materials, titanium alloys, titanium blocks, and Titanium Forgings, redefine reliability and precision for your most demanding projects.

Unmatched Precision: Powered by Advanced CNC Machining

Every titanium ring we produce is a testament to the power of cutting-edge CNC technology. Our state-of-the-art machining centers, operated by skilled technicians, ensure:

Micron-level accuracy: Tolerances as tight as ±0.001mm, guaranteeing consistent fit and performance across every batch—critical for applications like turbine seals, bearing races, and medical instrument components.

Complex geometric capabilities: From simple circular rings to intricate grooved, flanged, or tapered designs, our CNC machines handle diverse specifications with ease, eliminating manual errors and ensuring uniformity.

Smooth surface finishes: Achieve Ra values as low as 0.8μm, reducing friction, enhancing corrosion resistance, and minimizing the need for post-machining treatments.

This level of precision isn’t just a standard—it’s a promise. Whether you need 100 identical rings or a small batch of custom-designed parts, we deliver consistency you can count on.

Premium Titanium Foundations: From Raw Materials to Finished Rings

The quality of our titanium ring machined parts starts with the materials we use. We source and process only the finest titanium substrates to match your application’s unique requirements:

Titanium Blocks: Our high-purity titanium blocks (99.99% purity) serve as the base for rings requiring exceptional chemical stability—ideal for chemical processing valves or semiconductor manufacturing equipment.

Titanium Alloys: We work with industry-proven alloys like Ti-6Al-4V (for high strength and heat resistance), Ti-5Al-2.5Sn (for cryogenic applications), and Ti-6Al-4V ELI (for biocompatibility), ensuring your rings perform in extreme temperatures, corrosive environments, or medical settings.

Titanium Forgings: For rings needing enhanced mechanical properties, we start with titanium forgings. Forged titanium offers superior strength and fatigue resistance, making it perfect for high-stress applications such as aircraft engine rings or industrial compressor components.

No matter the material, every input undergoes strict quality checks—including chemical composition analysis and mechanical testing—to meet ASTM, AMS, and ISO standards.

Why Choose Our Titanium Ring Machined Parts?

In a market flooded with generic components, we stand out by prioritizing your success. Here’s what makes us your trusted partner:

Material Versatility: Whether you need pure titanium for biocompatibility, an alloy for strength, or a forging for durability, we have the right titanium materials to match your project’s needs.

Customization Expertise: Our engineering team collaborates with you to turn designs into reality—from adjusting ring dimensions and thickness to adding specialized features like keyways or threaded holes.

Rapid Turnaround: With in-house CNC machining capabilities and a streamlined supply chain for titanium blocks and forgings, we meet tight deadlines without compromising precision.

End-to-End Quality Control: From material selection to final inspection (including coordinate measuring machine (CMM) testing), every step is monitored to ensure your rings exceed expectations.

Elevate Your Applications with Precision Titanium Rings

Whether you’re building a next-generation aircraft engine, developing life-saving medical devices, or optimizing industrial machinery, our high-precision titanium ring machined parts are engineered to enhance performance and reliability.

Contact us today to request a custom quote, share your design specifications, or learn how our titanium materials and CNC machining expertise can solve your unique challenges. Let’s create components that stand the test of time—together.