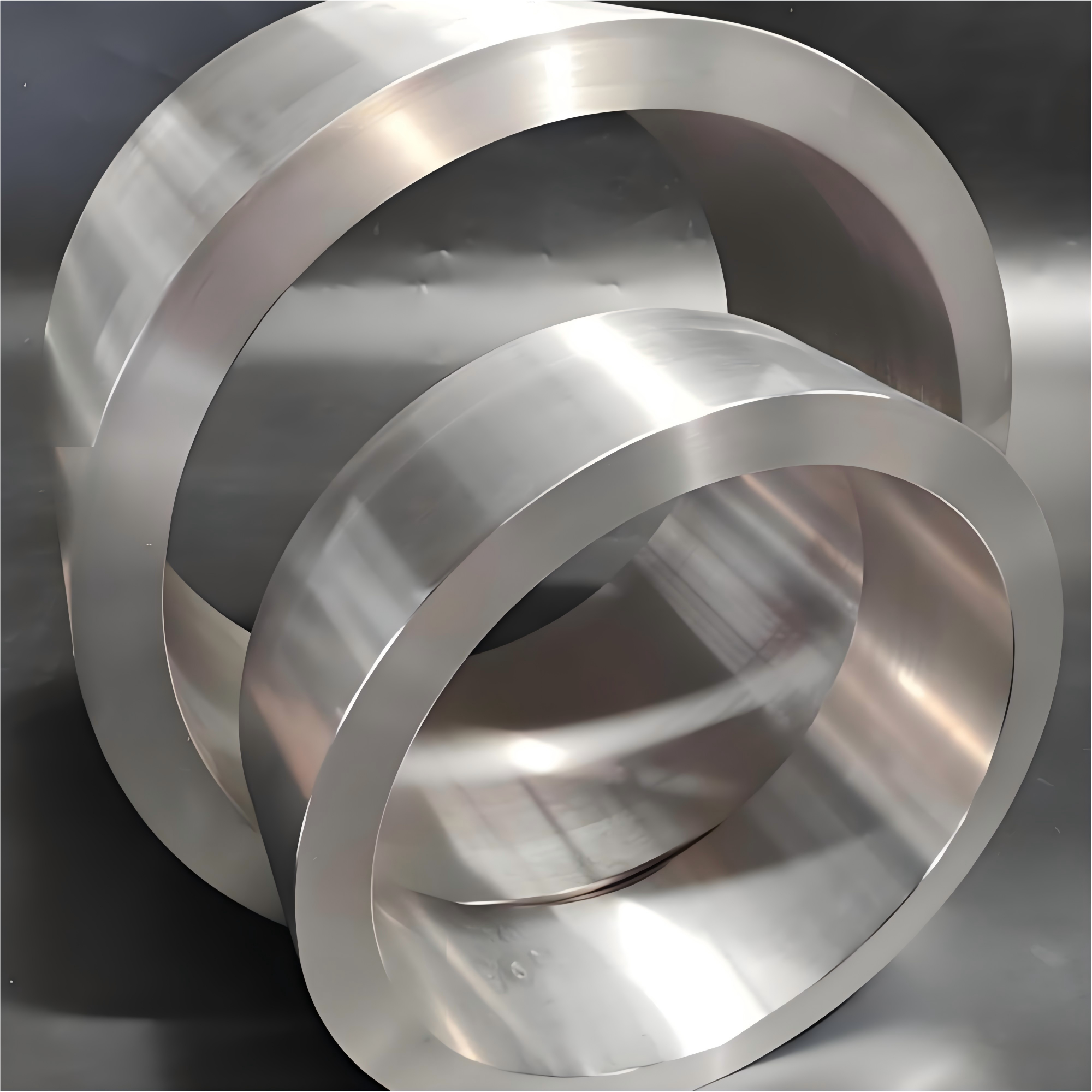

Corrosion-Resistant titanium alloy Forging Ring for Industry: The Ultimate Solution for High-Performance Applications

In industries where durability, strength, and resistance to harsh environments are paramount, Titanium Materials have emerged as a game-changer. Among these, titanium alloy forging rings stand out as a critical component, offering unmatched performance in demanding sectors such as aerospace, chemical processing, marine engineering, and energy production. Why Titanium Alloys?

Titanium alloys combine the inherent advantages of pure titanium—such as lightweight properties, excellent corrosion resistance, and biocompatibility—with enhanced mechanical strength and thermal stability. These alloys are engineered to withstand extreme temperatures, high-pressure conditions, and aggressive chemicals, making them ideal for applications where traditional metals fail.

Titanium forgings are produced through a precision manufacturing process that involves shaping the metal under high pressure and heat. This method eliminates internal defects, refines the grain structure, and enhances the material’s overall strength and fatigue resistance. When applied to titanium rings, forging ensures uniformity, dimensional accuracy, and superior structural integrity, critical for components subjected to cyclic loading or rotational stresses.

A titanium ring forged from high-grade alloy offers several key benefits:

Exceptional Corrosion Resistance: Titanium forms a stable oxide layer that protects against corrosion, even in chloride-rich environments like seawater or chemical plants.

High Strength-to-Weight Ratio: Titanium rings are significantly lighter than steel counterparts while maintaining comparable or superior strength, reducing energy consumption and improving efficiency.

Thermal Stability: Resistant to cracking under extreme temperatures, titanium rings perform reliably in both cryogenic and high-heat applications.

Longevity: With minimal maintenance requirements, titanium components outlast other materials, reducing lifecycle costs and downtime.

Industrial Applications

Aerospace: Used in engine components, landing gear, and structural parts where weight savings and durability are critical.

Chemical Processing: Ideal for reactors, valves, and pumps handling corrosive substances.

Marine Engineering: Withstands saltwater corrosion in offshore drilling, shipbuilding, and desalination systems.

Energy Sector: Essential for oil & gas exploration, nuclear reactors, and renewable energy infrastructure.

Conclusion

In an era where industrial efficiency and reliability are non-negotiable, corrosion-resistant titanium alloy forging rings provide a future-proof solution. By leveraging the unique properties of titanium materials, manufacturers can achieve unparalleled performance, reduce operational costs, and extend the lifespan of critical components. Whether in aerospace, chemical processing, or marine environments, titanium rings forged to precision represent the pinnacle of engineering excellence.

Invest in titanium—where strength meets sustainability.